Impact Stories

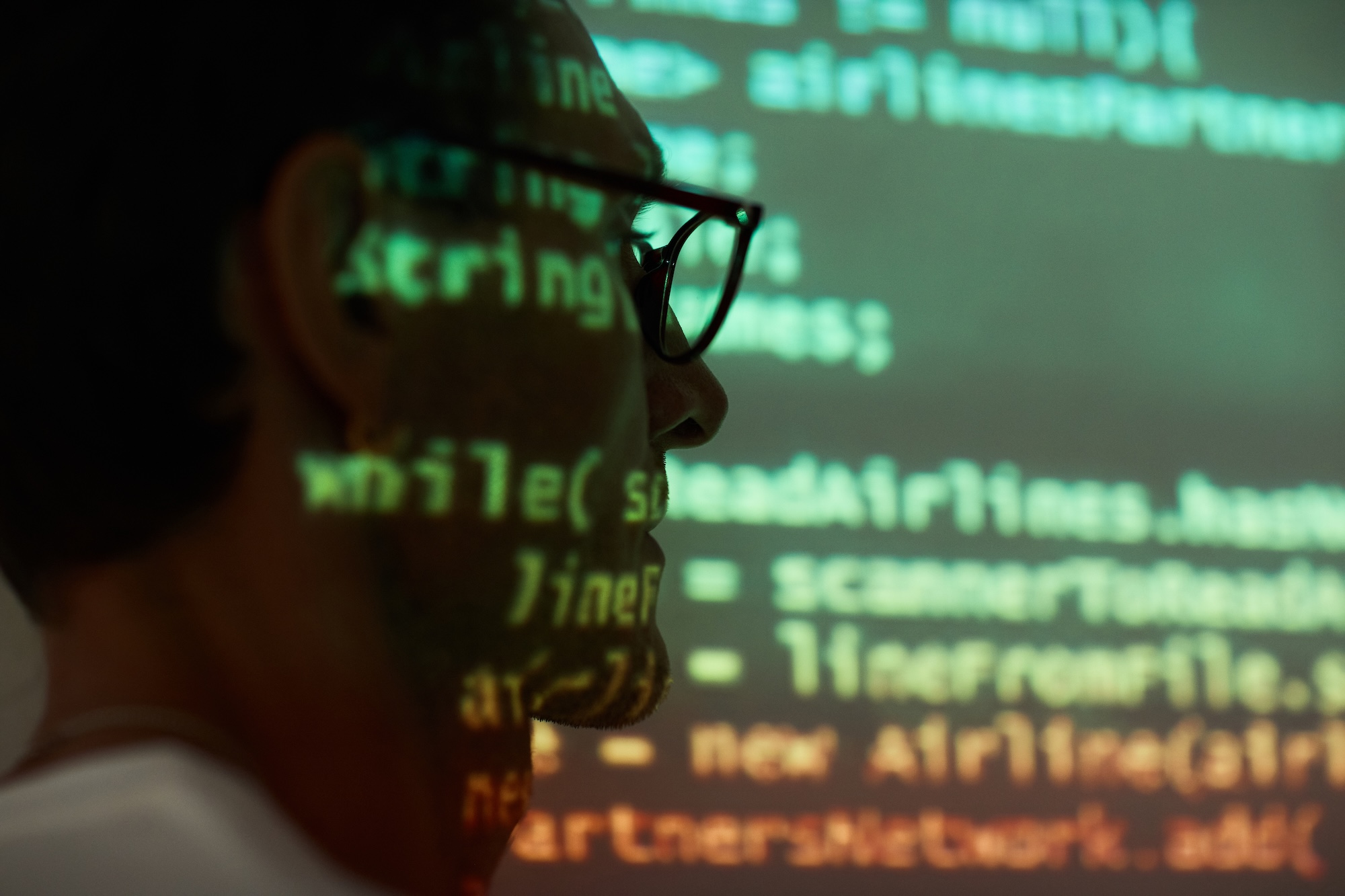

Ugandan youth are innovating a climate resilient chicken value chain

Thursday, March 6, 2025

By Barbara Mugwanya Zawedde and Owen Singura

As Uganda grapples with the consequences of climate change, including unpredictable rain patterns and increasing temperatures, there is a threat that agriculture will produce less and cost more. This is pushing many farmers to the edge of financial sustainability. In the chicken value chain, producers complain about the rising costs of feed, the scarcity of water, the increase of disease and pests leading to heat stress and high mortality rates. Climate-resilient solutions are needed urgently.

The National Agricultural Research Organization (NARO) of Uganda has introduced the Greening the Chicken Value Chain project to increase climate resilience for actors along the chicken value chain, with special focus on youth. A cohort has dedicated itself to innovation to address this challenge.

NARO collaborated with Gudie Leisure Farm (GLF), a private company, to organize the first Chicken Value Chain Climate Resilient Innovation Challenge in Uganda. Fifty-four submissions were received from innovators between 18 and 35 years old from across national regions. Twenty semi-finalists were enrolled in a NARO Intellectual Property and Entrepreneurship mentorship program, and an opportunity to showcase their innovations at a multi-stakeholder coordination meeting for researchers, large scale farmers and financial institutions who represents different parts of the chicken value chain.

Top ten innovations, representing both hardware and software developments were ranked by a forum of youth agri-preneurs based on their relevance to daily agribusiness. The top five finalists are being supported by the project to scale–up and undergo peer evaluation to increase their readiness for potential adoption.

The best innovation was a Smart Kuku Brooder, an automatic control box designed to regulate heat in a brooder. Mortality is most acute from Day 1 to Day 21 after hatching, mostly due to temperature fluctuation in the brooder. This solution provides an affordable, environmentally friendly and energy-efficient product to decrease mortality from cold-stress in this vulnerable period.

NARO-MUZARDI Test Case

Before 2024, NARO-MUZARDI, like many poultry farms in Uganda, used charcoal for brooding -- an energy source that is unreliable, labor-intensive and polluting. With this method, chicks must be watched 24/7. When the institute adopted the Smart Kuku Brooder in November 2024, mortality fell by 10%, and 24-hour human supervision was no longer necessary. Instead, technicians receive SMS messages on their phones when their attention was required to keep chicks warm. The project is now supporting the Smart Kuku team to integrate a solar component for their system.

Olal Jerome explains how the Agro Vision Incubator a 10-eggs capacity prototype works during the national multi-stakeholder coordination meeting.

Solar Incubator

Most smallholder farmers in the country rely on natural incubation (i.e. roosting hens), but the efficiency of Mother Nature alone is limited. Many farmers instead use hatcheries – but access to hatchery services is inconsistent across the country. Agro Vision Uganda, the first runner-up, reinvented the solar incubator. It offers an environmentally friendly and low-cost small-scale incubator that is affordable to modest farmer groups. The incubator, being evaluated at NARO-MUZARDI, has a capacity of 300 eggs, and uses hybrid energy sources to reduce reliance on fossil fuel generator. The latest version includes an option for remote monitoring via a mobile app, which allows farmers to control and monitor incubator conditions remotely.

Plant Based Protein Sources

Protein is becoming an increasingly expensive component of both human diets and animal feed, creating a "protein dilemma"—competition between humans and livestock for the same food sources. It is difficult to consistently source sustainable, protein-rich feed ingredients that are also environmentally friendly. A central challenge is to produce protein while minimizing carbon emissions. Plants including Moringa, Russian Comfrey and Azolla offer promising high-protein feed supplements. Young innovator, Nkumba Ashraf, is producing chicken feed pellets from dried Azolla. This aquatic plant contains 20–35% crude protein and requires minimal water to grow. It thrives in shallow water, typically just a few centimeters deep, making it a climate-resilient feed option. Assessment of the economic feasibility of integrating Azolla into poultry production is ongoing.

Research and innovation, a core mandate of NARO, drives sustainability fueled by the ingenuity of Uganda’s youth. Actors along the chicken value chain will benefit from this first cohort of youth innovators who will continue to be supported by the NARO and GLF through the development of beta tests for potentially marketable solutions. We are grateful to Science for Africa Foundation Grand Challenges Africa for enabling support of these youth innovators.

About the Author(s)

Barbara Mugwanya Zawedde

Zawedde is a grantee of the SFA Foundation's Grand Challenges Africa initative, climate and agriculture adaptation cohort.